Here's a fun project that combined 3D printing, auto repair, and wood work:

Replacement console cover for a '97 Ford Ranger pickup truck.

Motivation:

My truck has a broken center console cover. This was one of those small annoyances that made my daily life slightly more miserable than necessary: I didn't have an arm rest while driving and anything stored in the console tended to drift around the cabin. If I ever needed to raise the console for three people to sit, everything dumped out between the seats. I ended up tying it closed with a length of string, which would inevitably slip off at the worst moment, flipping the spring-loaded cover open.

Even used replacement parts for this thing are wildly expensive, so I decided to fabricate a replacement out of spare plywood and wood plus a 3D printed clip.

The idea of having a bit of wood trim in my super cheap pick up truck seems impossibly, hilariously luxe.

Fabrication 1: Wood

The top was easy enough - just trace and cut with a jigsaw, then route the upper edges with a 3/8" roundover bit.

The next bit was slightly harder - the hinge doesn't connect to the top with a 90 degree angle, so I cut an adapter from some spare 1 by 4 by matching the angle on the plastic to the table saw blade. The end result wasn't precisely the right angle, but it was close enough. I could have made the wooden adapter smaller, but I didn't want to risk splitting due to repeated stress and heat.

I dry-fit the pieces and screwed them together for a quick test, then disassembled everything so I could sand down to 200 grit and apply some pre-stain and three coats of polyacrylic. I chose polyacrylic instead of (more durable) polyurethane because pickup truck cabs are tiny and very hot, and polyacrylic releases fewer fumes than polyurethane.

Fabrication 2: 3D design and print

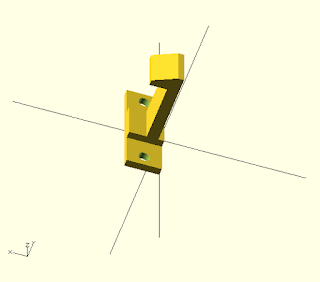

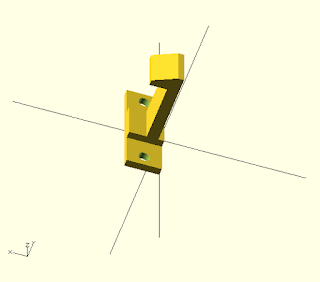

The final step was to 3D print a replacement clip to keep the lid closed. I don't know exactly what the original one looked like, but I made some guesses based on measurements of where it is supposed to go and some photos of replacement parts. It took only four iterations of printing, making an adjustment, and reprinting before I was happy with the results. I definitely appreciated the openSCAD paradigm for making those measurement adjustments quick and painless.

Since this is such a dimensions-driven project, instead of firing up a GUI-based cad program, I decided to use this project as an excuse to learn a little more openSCAD syntax. So with

this cheat sheet's help, and a few iterations with the 3D printer, I was able to make a cute little clip that screws into the lid of my console with about 19 lines of code.

Final assembly and testing.

I like the look of red plastic against light wood, and there's no way to hide the clip, so I chose to highlight it in red instead.

The end result works! I now have a pleasant place to rest my arm while driving, and when I need more seating, the contents of my console don't go everywhere!